Why Bar code scanning technology?

Today, the bar code is everywhere. This simple technology is synonymous with data capture. In fact, we have the ability to capture and interpret this data in our pocket most of the time. But the technology didn’t start out being so prevalent. Its development alone took over a quarter of a century from concept to production!

Bar codes and scanners in commercial use

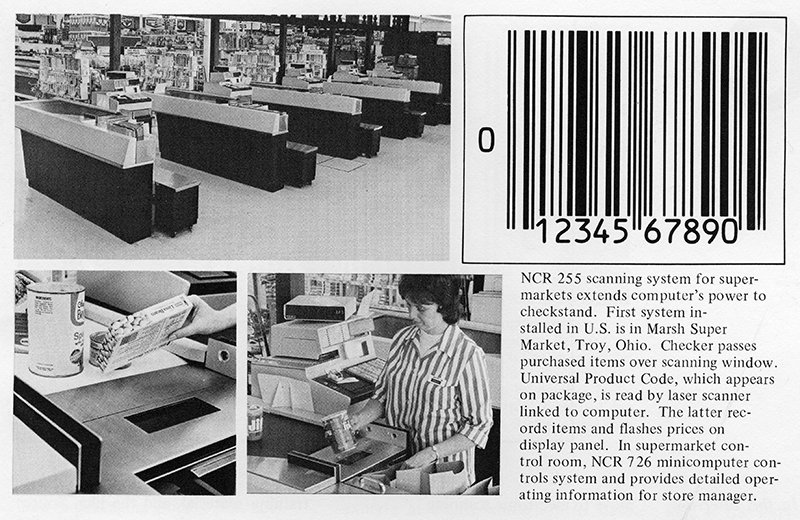

Just after 0800 on June 26th, 1974, in the small town of Troy, Miami County, Ohio the commercial world was revolutionised when a checkout cashier at Marsh Supermarket first scanned an item marked with a Universal Product Code (UPC) or ‘barcode’.

The first bar code “shopper” was Clyde Dawson, who was head of research and development for Marsh Supermarket; the cashier who “served” him was Sharon Buchanan, the first item scanned was a pack of Wrigley’s Juicy Fruit chewing gum. This was chosen as nobody thought it would be possible to print such a small and accurate bar code on the side of a packet. But the ever-innovative Wrigley’s had found a solution to the problem. And the rest, as they say, is history…

Want to know another random fact about Wrigley’s gum?

The origins of the bar code

The very first bar code was drawn in the sand by inventor Joe Woodland in 1949 decades before the technology was there to support it. But there’s more to this story than a daydream on a beach.

The story begins with an overheard conversation between a distraught supermarket manager and a dean at Drexel Institute of Technology in Philadelphia. The manager was pleading for a way to get shoppers through his store more quickly. The dean dismissed him and the request, but a junior postgraduate, Bernard “Bob” Silver, overheard and was intrigued. Bob knew the inventor, Joe Woodland (who had graduated from Drexel in 1947) and when he heard about it, was interested in the challenge.

He realised scanning a code would be faster than a cashier finding a price tag and typing it in. This would also help speed up the sale and the regular stocktaking. So confident he would come up with a solution, Joe left graduate school in 1948 and moved to Miami Beach. He cashed in some stocks and began work. His lightbulb moment occurred in January 1949 but his brilliant, yet simple solution would not manifest until many years later.

His solution was inspired by morse code, which he had learned in the Boy Scouts:

“I remember I was thinking about dots and dashes when I poked my four fingers into the sand and, for whatever reason – I didn’t know – I pulled my hand towards me and I had four lines. I said ‘Golly! Now I have four lines and they could be wide lines and narrow lines, instead of dots and dashes. Now I have a better chance of finding the doggone thing.’ Then only seconds later, I took my four fingers – they were still in the sand-and I swept them round into a circle.”

Joe Woodland

Scanning technology innovations

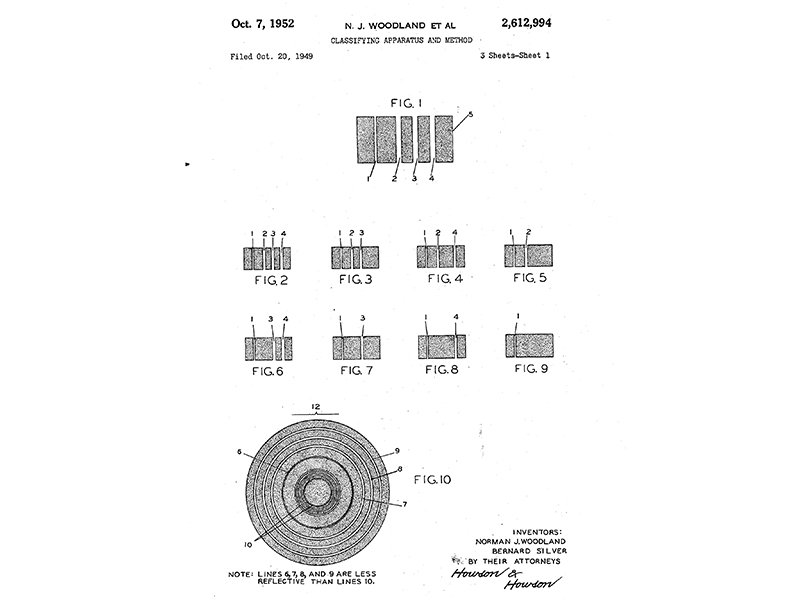

Bob and Joe went back to Philadelphia and tried to get a working system going with the technology available. They filed a patent in 1949, it was granted in 1952, and a working prototype featuring a 500-Watt incandescent lightbulb, and an oscilloscope used to ‘read’ the code was constructed. However, it was considered by an objective evaluation that the concept was 20 years ahead of its time. They had the concept, but they lacked the microcomputer and critically a very bright light to ‘read’ the bar code.

It wasn’t until July 1960 that a solution appeared. A Light Amplification by Stimulated Emission of Radiation (L.A.S.E.R) was revealed by Hughes Aircraft Company of Culver City California. Its ability to produce a constant, concentrated beam of light, had potential applications across science and communications. This was a game-changer – however its inventors never considered it would become the essential part of a grocery scanning device.

So, although a key component had now been invented, the story stalls. Until a booklet was published by the supermarket chain, the Kroger Company in 1966. It signed off with a wish for a better future…

“Just dreaming a little . . . could an optical scanner read the price and total the sale. . . . Faster service, more productive service is needed desperately. We solicit your help.”

The Kroger Company, 1966

Kroger’s business was not electronics, but had a dream, so went looking for a partner with the expertise. They found a small research team at the Radio Corporation of America (RCA) that was looking at new projects. One of which was the bar code. After dismissing some ideas, one of which saw customers pick out punch cards that identified what they wanted to buy and presented them to a cashier, who retrieved the goods from a store. Another was a patent for a system in which the supermarket shopper threw everything into a basket, which was pushed under a scanner that identified each item and printed out a bill (but more on that later!).

However, they soon found Bob and Joe’s patent, and realised they might be onto a winner.

The ‘target’ for scanning codes

The problem with the target style of code in the patent was printing it – although readable from multiple angles the codes were difficult to print accurately. RCA persevered and on July 3rd, 1972, the first automatic scanning kiosks were trialled at the Kroger Kenwood Plaza in Cincinnati. It was not long before the bulls-eye barcode hit the target with superior sales figures! But this was just one store in a supermarket business worth billions. If the laser and barcode were going to change the world they would have to be near universal.

In comes the Ad Hoc Committee of the Universal Product Identifier Code. Which was formed with one sole purpose – the introduction of a Universal Product Code (UPC). The UPC, would become a code of some description that could be common to all products sold in supermarkets and imprinted by manufacturers and retailers. It would carry information about the product, the company that made it and so forth. The in-store computers would ‘read’ this with a scanner and introduce their own variations (special offers or reductions, etc).

Manufactures were resistant, other methods had resulted in a lot of cost and the concepts were ultimately discarded or adapted. Some felt the code would spoil their product physically and in appearance. Others did not want the obligation of printing at all. It would take four years to arrive at a workable proposition to put to the whole industry.

Universal standards for scanning bar codes

Ultimately it fell to seven companies to submit concepts to the Symbol Committee (an offshoot of the Ad Hoc Committee). RCA felt after their successful trial in Cincinnati they were the only real contender – except at the last minute, International Business Machines (IBM) made a surprise bid – it had no technology to show the committee and its decision to enter does seem like an afterthought, but it had one major element going in its favour – one Mr Joe Woodland.

Joe was not responsible for the Universal Bar Code submitted – that was down to George Laurer, who had taken the specification handed out by the Symbol Selection committee and designed a solution.

Although there was scepticism in IBM, George was convincing enough to be given the go-head with a rectangular bar code. A division of IBM built a prototype scanner, and George’s Universal Product Code was tested. “There were many sceptics in IBM,” George recalled, “not the least of whom was [his boss] B.O. Evans himself. However, at the end of a flawless demonstration for Mr. Evans, we had our ace softball pitcher pitch beanbag ash trays, with symbols on the bottom, as fast as he could over the scanner. When each one read correctly, Mr. Evans was convinced.”

After a strict set of trials by the Symbol Selection Committee on March 30th, 1973, they awarded IBM and George’s code as the winner. For Joe it was a strange experience to witness his original concept founded in lines in the sand on Miami Beach in 1949 to be realised 24 years later. All it took was the release of a low-priced laser scanner, a reliable, inexpensive microcomputer, a universally accepted standard to decipher the alternating thick and thin, black and white lines.

Widespread bar code scanner technology adoption

As with many inventions it took big names to adopt before it took off. Kmart being the first adopter, followed closely by companies like Walmart who deal in thousands of goods needing to be catalogued and tracked. The barcode really took off in the grocery and retail business in the 1980s and at the same time it began to transform manufacturing and marketing. Anything needing instant identification came under its purview and in 2004, Fortune magazine estimated that barcode was used by 80-90% of the top 500 companies in the US.

The technological advancements soon led to process changes, cultural acceptance, data collection and ultimately data processing to bring far more to the table than speeding up checkout times. Its greatest value to businesses is reflected in the ability to provide hard, statistical evidence for what sells and when. It has transformed market research and powers marketing and the once- feared ‘death-ray’ now is a had held device tracking everything from gum to televisions, pipe fittings to hospital patients.

Keeping up with scanning technology, 1D and 2D bar codes

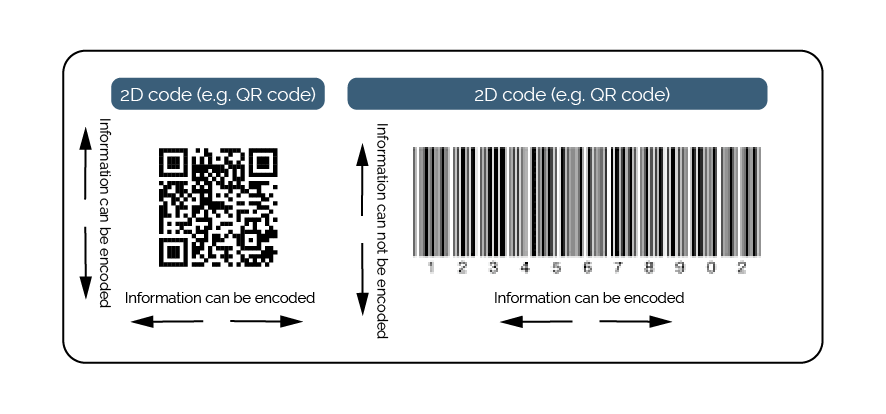

Up until now, we have been talking about 1D barcodes (patterns where data is encoded in only one direction). Now there are 2D barcodes (where data is encoded in two directions) available allowing for more information to be relayed in essentially the same space.

Although these have evolved from UPC codes they still use largely the same technology to work. Even though there are now many different versions including EAN codes (larger data in high density printed codes), Code 39 (Automotive and Defence), Code 128 (logistics and transportation), ITF (packaging), Code 93 (logistics), Codabar (Logistics, Healthcare and education), GS1 Databar (Retail and Healthcare), MSI PLESSY (inventory and retail).

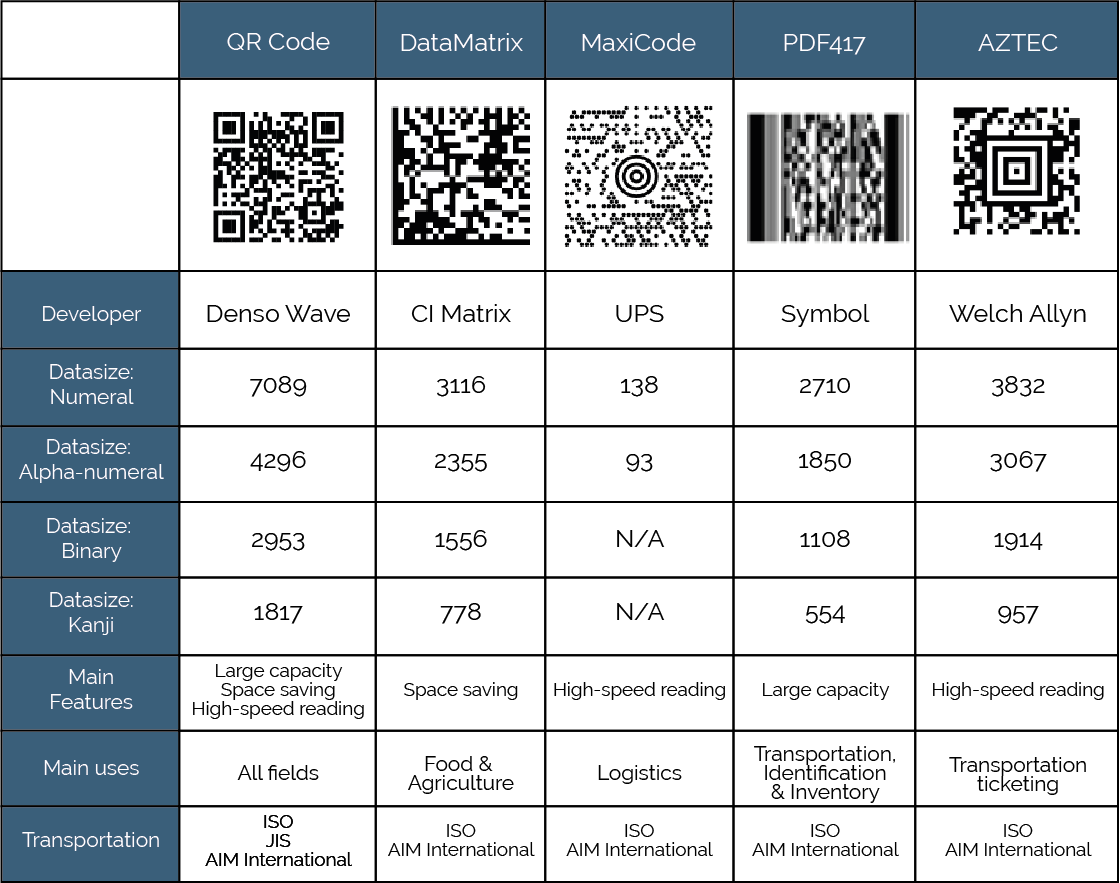

However, 2D barcodes hold far more data and include QR codes, DataMatrix (electronics), MaxiCode (logistics), PDF417 (large data volume) and AZTEC (Transportation tickets) they still are dependable, universal, easy to reproduce, relatively small and low cost just as 1D bar codes.

Today, technology has developed, the need for data capture and processing has grown exponentially. As a result, the need for scanning has grown too. It now has to be faster, more accurate, process more information with less intrusion. Today’s technology, RFID, is as much of a game changer as the original UPC bar code.

Radio Frequency Identification Scanning (RFID)

RFID is a form of wireless communication that incorporate electromagnetic or electrostatic coupling in the radio frequency portion of the electromagnetic spectrum to uniquely identify an object. RFID technology has and continues to transform the supply chain, empowering customers and expedite operations as well as delivery times. A direct line of sight is no longer required for a camera or laser to read a code. Instead, a mobile phone can be used to ‘read’ the RFID code on an item of interest. This can launch video, show information or kick start an automated process like payment, data transfer, order management or shipping.

In fact, thanks to the advent of RFID, the concept dismissed by RCA, in the early 1970s, of scanning a whole basket of shopping in one go is now very much a reality!

Seamless inventory tracking with RFID

It doesn’t stop with Shopping – Inventory tracking becomes simple too, with RFID. RFID tags can allow for automated and fully accurate inventory counts:

- Streamline operations and make human errors a thing of the past.

- Reduce costs whilst minimising time and errors from manual inventory counts.

- Warehouses will know exactly where items are and when they are being shipped.

- Automate orders and track every item across its entire journey.

RFID technology is as much of a game-changer as the original UPC barcode. It is a key element of the Internet of Things (IoT). Just as bar codes made groceries smart in the 1980s, RFID chips can make mundane items smart and enable them to communicate intelligently, sharing data across devices and applications.

Customer service will improve substantially due to faster scanning and processing. Not only will customers save time, but they will also be able to track their items at every part of their journey. They will use their smart devices to scan items for quick retrieval of information or even payment. As costs drop and business cultures and technology evolve, data becomes more important. As we see these needs grow, we will see more use of RFID technologies.

Improve accuracy, efficiency, streamline process & save time

The future is RFID but what of the humble bar code?

The bar code continues to this day. It has evolved to the numerous versions listed earlier band each has a specific role, being used when most appropriate. But what of out Miami Beach day dreamer, with a vision so advanced of its time?

After nearly 50 years of being a footnote, the one-time boy scout who remembered his morse code was recognised for his contributions to the story of the bar code. In February 1992, President George Bush was spotted at a grocery convention, marvelling at how a bar code scanner was able to read a damaged bar code. A few months later Bush presented Joe Woodland with a National Medal of Technology.

So, the next time you are at a beach take a moment to daydream. Run your fingers through the sand and you too might be formulate an idea that might change the world.